LOW NOISE WHEELS:LUCCHINI SOLUTIONS

1. Introduction

Urban areas are particularly sensitive to railway noise. Both the population density and railway traffic increased in the suburbs where trains travel relatively fast and build-ings are relatively high, leading to situations where the use of noise barriers is almost useless.

A greater and increasing consciousness of citizens led to a lower tolerance of the visual impact of noise barriers also in those case where they are relatively more effec-tive, i.e. where the railway line is close to low height houses.

Some regions with particularly nice landscape start discarding the possibility of us-ing noise barriers to preserve the environment from their intrusive impact.

It is evident that in these situations it is necessary to implement noise reduction measures at the source. The exact responsibility share of noise creation in the medium to low speed range is hard to be determined but, quite likely, both the track and the ve-hicles will emit a significant part of noise, leading to the conclusion that treating one of the two components may have limited effect.

Lucchini Sidermeccanica SpA manufactures wheelsets since 150 years and has de-veloped a family of wheels with limited noise emission. This paper is intended to give some basic description of each low-noise wheel and to give the details of its application, including the possible limitations.

2. Wheel noise reduction principles

The description of noise generation mechanism details lies outside the scope of this paper. It can be generally said that the rolling of a steel wheel on a steel rail is by far the responsible of the majority of noise for speeds up to approximately 250 km/h, where the aerodynamic noise takes importance and can become the prevailing source. At very low speeds, below 30-40 km/h, the noise may come from auxiliary equipment of locomo-

tives and coaches, like engine fans, air compressors, HVAC systems and so on. All these sources can be optimised and their influence is decreasing with their level of so-phistication.

Rolling noise is generated by wheel and rail vibrations which interact with air by the so-called fluid-structure coupling. This is the usual mechanism for all noise generation but the noise generated by aerodynamic sources. Vibration is in turn generated by the combination of the individual dynamic response of each component and the combined wheel and rail roughness, which is ultimately the input to the system.

Wheel noise, or generally speaking the noise coming from the lower part of the train and the relevant part of the track, can be limited by using bogie shrouds; although their effectiveness was proved in some cases, nevertheless their use did not gain popularity in the rolling stock market due to some disadvantages, mainly a lower accessibility to the bogie area that limits visual inspections and the limited effect with the usual vehicle and track gauges. The possible solutions on the noise propagation path are therefore limited to noise barriers whose use is not envisaged for the reasons described in the previous chapter.

A wheel manufacturer has no control on the track maintenance parameters and has limited or no control on vehicle maintenance. The only possible assumption for a wheel manufacturer is therefore that of “average” boundary conditions, and the noise measures that he can adopt are limited to the wheel itself.

As noise generation is directly linked to vibration amplitude, the natural dynamic behaviour of the wheels must be optimised in order to reduce vibrations under service conditions. Some common methods to reduce the amplitude of vibrations under a given input are vibration decoupling, dynamic absorbers and added damping. Each of these measures has specific fields of application.

It must be noted that the structural damping of solid and tyred steel wheels is pretty low, in the order of 10-4 of the critical damping. Fortunately forces at the wheel-rail con-tact automatically introduce the so-called “rolling damping” which naturally reduce wheel vibrations and generated noise, but nevertheless the amount of noise emitted by the wheel is still too high. Any treatment to reduce wheel vibrations must therefore be more effective than the natural rolling damping effect to be noticeable in terms of noise reduction.

Vibration decoupling is not applicable to wheels as the input is typically broad band. Wheel and, especially, rail roughness can be assumed as approximately random proc-esses and there is no way, therefore, to design a wheel whose natural frequencies are not excited by combined roughness.

Dynamic absorbers are designed to work at the natural frequencies of the wheel, that considerably change with wheel wear and subsequent reprofiling [1]. Their effective-ness can therefore be quite high with a new wheel tread but may decrease during the useful life of the wheel.

A common method to introduce damping in a highly resonating relatively flat struc-ture (like a steel sheet or a cover) is to stick to the surface a rigid plate with some damp-ing material in between. This treatment, known as “constrained layer damping”, is well known in acoustics and its application to wheels leads to a broadband damping that is

relatively insensitive to wheel tyre shape changes. Wheel reprofiling even increases the efficiency of constrained layer damping as reducing the overall mass leads to a better ef-fectiveness of the unmodified web portion of the wheel.

3. Lucchini approach to wheel treatment

Regardless of the damping principle, a large distance separates a prototype from a commercial product. After a treatment has been conceived and successfully tested in the laboratory, an even larger task has to be accomplished by the manufacturer. Safety certi-fications, positive feedback from test runs, a satisfactory real life behaviour and, over all, a reasonable life cycle cost united to good acoustic performance are to be obtained and assessed.

Lucchini started the first tests during the mid ‘90s, evaluating some solutions that were available at that time [2].

A long and extensive research on potential market needs and on competitor’s prod-ucts led to the conclusion that a constrained layer damping could have been a good starting point. Lucchini developed at that time its first low-noise wheel treatment, named Syope® by the name of the Greek goddess of silence, whose target was the treatment disc-braked vehicles without speed limitation; other products were then de-veloped like the Galene® treatment for tram wheels, the Syope Braw® treatment for wheels with web-mounted discs and the Hypno® wheel treatment that was primarily in-tended for tread-braked vehicles (typically freight wagons). The remaining of this paper is devoted to the description of these products.

4. The Syope® wheel treatment for disc braked wheelsets

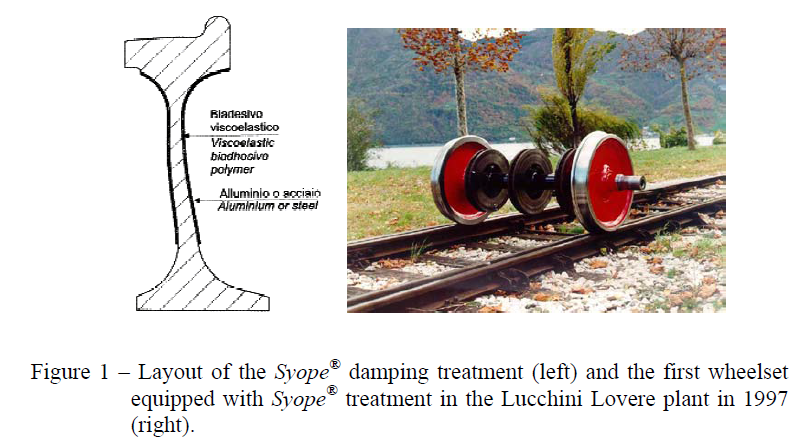

The main concerns about the use of a constrained layer damper applied to the wheel were about durability and reliability. Lucchini developed the application with 3M Italia, the Italian branch of the world leader in the development of adhesives and polymers (Fig. 1)

The solution was developed starting in 1996 and led to the production of some test wheels that were mounted on the ETR500 Italian high speed train during 2000. Some of these wheels have finished their life cycle after 1.100.00 km (5 years) without any prob-lem and some have run at more than 350 km/h on the test train that holds the Italian railway speed records.

Tests performed in 2000 by two independent teams (University of Florence on be-half of Trenitalia [3] and Deutsche Bahn [4]) showed a reduction of 4.0 to 5.2 dB(A) in the overall maximum pass-by level LpAmax at 7.5 m in the 190÷295 km/h speed range. Data on noise reduction during tests can be found in a number of papers [5,6] and a complete description of the Syope® project will be given at the next International Wheelset Congress [7].

All safety certifications were obtained in 2002 [8] and allowed the application to several types of rolling stock that range from local, narrow gauge railways to high speed state-of-the-art trains. In all cases considerable performances and, when comparative data were available, relevant reduction of the overall noise level were obtained, as fol-lows:

• for the Stadler GTW 2/6 trains for the Ferrovia della Val Venosta (Merano-Malles) a maximum pass-by level LpAmax at 25 m of 74 dB(A) with engines off, when the Italian laws require a maximum of 81 dB(A) starting from 2012 [9]. It is clear that in this case the rolling noise is negligible and the ef-forts may be concentrated on the engine exhaust system;

• for the Circumvesuviana case, an overall noise reduction of 4.5÷5.0 dB(A) in the speed range 50÷90 km/h [10]. After these brilliant results, the retrofit of the entire fleet was decided and it is currently under implementation.Further new trains, manufactured by Firema, will be equipped with Syope®; this will allow the Railway Administration to respect the noise emission limits with-out using noise barriers along the line.

After the installation of the treatment on the Alstom Pendolino for Czech Republic, which uses the same wheels of ETR500 and that has therefore similar performances, also the whole fleet of the new Alstom Nuovo Pendolino for Trenitalia (ETR600) and Cisalpino is equipped with this treatment.

5. The Galene® wheel treatment for elastic and tread braked wheels

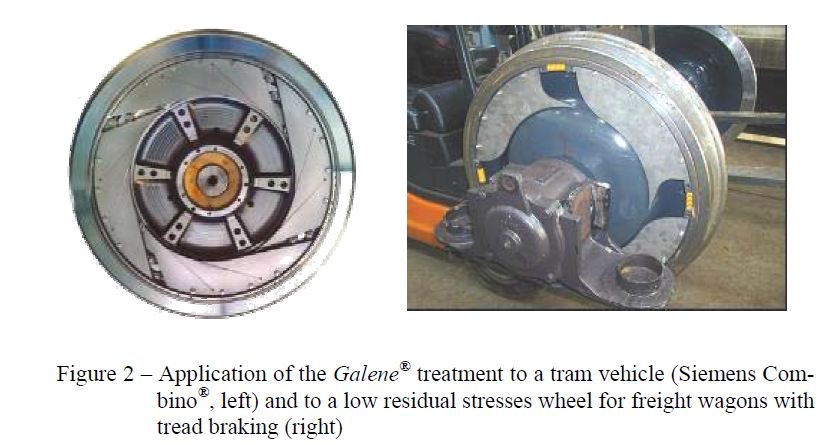

Some wheels have thermomechanical or geometric constraints such that the use of a damping treatment of the wheel web is not possible. Two examples are the elastic wheels for trams and the wheels for freight wagons (Fig. 2).

For these fields of application a damping system was developed by using damped fins attached to the outer part of the wheel (to the tyre for elastic wheels). In the case of tread braked wheels, large displacements due to thermal expansion during braking are accommodated by pre-loaded springs.

The fins are designed to offer the maximum damping when subjected to bending, and their design changes considerably from wheel to wheel.

The treatment gives brilliant results especially for the suppression of squealing noise typical of tram systems. In the case of tread braked wheel there were some concerns about the durability of the polymer during long sustained braking; the overall cost is in any case too high for a freight wagon and it was then decided to develop the Hypno® wheel treatment that will be described later.

6. The Syope Braw® wheel treatment for wheels with brake disc mounted on the web

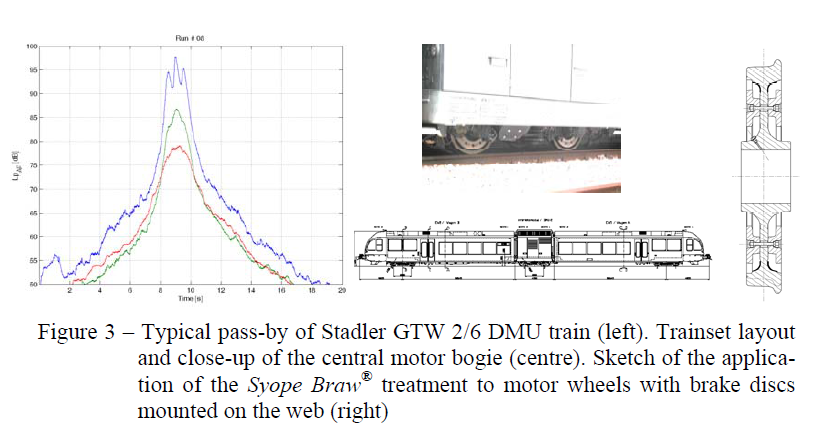

Already mentioned tests performed in the Val Venosta railway with Syope® wheels mounted on the Stadler GTW 2/6 train showed that the overall noise can be further re-duced. That train has in fact two trailed bogies at the ends and a motor bogie in be-tween. It can be seen (Fig. 3) that the maximum noise level comes out from the motor bogie that has the brake discs mounted on the web, and that the noise coming out from it is barely 3 dB(A) greater than that coming from the Syope® treated wheels, while a 4 to 5 dB(A) difference was expected.

A study was started to investigate the behaviour of the wheel with brake discs mounted on the web and it was found that the application of the discs introduce some damping but that it is not sufficient to ensure the desired low noise characteristics of the wheel.

Braking introduces heat and the wheel web shape is not regular, having holes and different machined portions; the only possibility to introduce a further damping was the development of a reduced Syope® treatment, limited to the accessible part of the wheel, just below the rim. Preliminary laboratory tests, conducted with different thickness of the constraining plate led to very promising results in terms of damping [11], showing a possibly better effect compared to that of the Syope® treatment with a lower mass. The treatment was named Syope Braw®, and it will undergo tests on the Stadler GTW 2/6 vehicle in Spring 2007.

7. The Hypno® wheel treatment for tread braked wheels

It is well known that freight wagons are by far the most important source of noise. Wheel roughness due to cast iron dominates rail roughness, and the only way to reduce noise is to use different brake blocks which leave the wheel smoother leading to noise levels similar to those of disc braked vehicle. The reduction of noise from the current situation is in the order of 8 to 10 dB(A).

Even if it is expected that the emitted noise will decrease to reasonable levels, freight trains normally travel during the night, when current European regulations give a strong penalty (+10 dB) to train noise. As a consequence, freight trains should be much quieter than passenger trains. The development of damping treatments similar or better than those already presented seems therefore unavoidable.

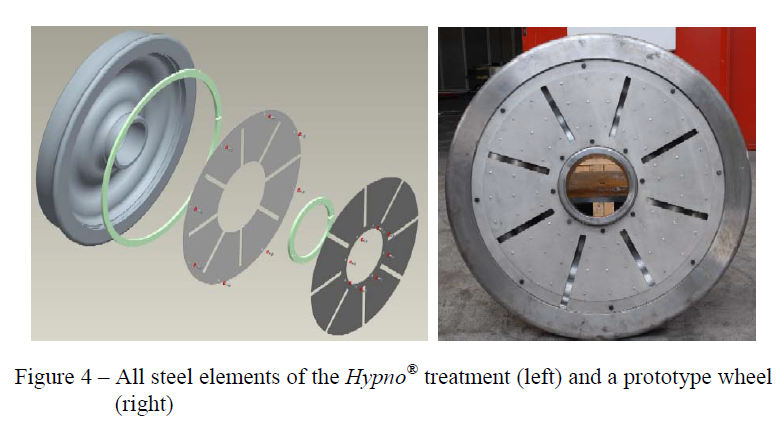

Constraints given by thermal inputs into the wheel rim are extremely severe and preclude the possibility of using any polymer or damping material. It was decided there-fore to change the technology of damping, using friction damping on a composite struc-ture fully made of steel.

Two discs are joined by means of rivets and are constrained elastically to the rim and to the hub. Modifications to wheel design are therefore limited and do not prevent the application to existing wheels (Fig. 4).

The principle of energy dissipation during bending remains as for the Syope® treat-ment but without a dedicated material, simply using friction of coupled and preloaded plates; to allow the wheel to cool down during and after braking some slots were left in the structure; the fins themselves may dissipate a non negligible quantity of heat helping the wheel to cool down. It is important to highlight that slots in the fins should have a limited impact on the acoustic performances of the treatment as it is intended as a damper and not as a screen.

The Hypno® wheel treatment is going to be developed in the frame of the FP6 Euro-pean funded research Project SILENCE and will be tested with the cooperation of DB, SNCF and Trenitalia.

8. Conclusions

Lucchini Sidermeccanica has developed wheel treatments that effectively can help to reduce railway noise at the source. In some cases, these treatments avoid the use of noise barriers, saving money and spreading the advantage on the entire railway network.

While some of the products described in this paper have already been accepted by train operating companies and infrastructure owners, for the others an intense and care-ful set of activities is planned in the future, always in the frame of co-operations be-tween the company and qualified R&D and industrial partners.

The only possibility to see a product widely accepted is to take into account since the very beginning all the aspects of life cycle cost and maintenance as well as good acoustical performances, and this has been by far the Lucchini philosophy since more than 10 years.

The outcome form this long process is the practical availability of solutions that limit or even prevent the use of noise barriers in all those situations where their use is inappropriate. Sophisticated financial scenarios [12, 13] show that the use of noise re-duction measures at the source are definitely better than noise barriers and this should facilitate the introduction of these measures.

9. References

[1] Cataldi-Spinola E., Glocker Ch., Stefanelli R., Götsch M., “Influence of the Wheel Diameter on the Curve Squealing of Railway Vehicles”, Proc. of Eu-ronoise 2003, Napoli.

[2] Cervello S., Bracciali A., “Development of a Vibro-Acoustical Methodology for the Design of Low Noise Railway Wheels”, Proc. of the World Congress on Railway Research WCRR ’97, vol. E, 157-163, Firenze, 1997.

[3] Bracciali A., Bianchi M., “Lucchini CRS Syope® damped wheels noise quali-fication”, Proc. of the 13th International Wheelset Congress, Roma, 2001.

[4] Degen K. G., Nordborg A., Martens A., Wedemann J., Willenbrink L., Bian-chi M., “Spiral array measurements of high-speed train noise”, Internoise 2001, Den Haag.

[5] Bracciali A., Piccioli F., “Experimental analysis of wheel noise emission as a function of the contact point location”, Journal of Sound and Vibration 267(3), pp. 469-483, 2003.

[6] Bracciali A.: Damped Wheels as an Efficient Measure to Reduce Railway Noise, Euronoise 2003, Napoli (on CD).

[7] Bracciali A., Cervello S. et al., “Lucchini Sidermeccanica Syope® Low Noise Wheel: the Story 1995-2006”, to be presented at 15th International Wheelset Congress, Prague, 2007.

[8] Italcertifer, “Relazione tecnica per ruota Syope”, Prot. 140, 28.08.2002

[9] Bracciali A., Cervello S., Moroder H., “Qualificazione acustica dei treni del-la Val Venosta”, Proc. of the Institution of Italian Railway Engineers (CIFI) conference on “Reconstruction of Val Venosta Railway”, Firenze, 2006.

[10] Borrelli A., Cervello S., “Syope®. La nuova ruota ferroviaria a ridotta emis-sione acustica sviluppata e prodotta da Lucchini Sidermeccanica”, Ingegne-ria Ferroviaria, vol 5, pp. 463-473 (2003)

[11] Lucchini Sidermeccanica product leaflets, September 2006.

[12] Oertli J., “The STAIRRS project, work package 1: a cost-effectiveness analysis of railway noise reduction on a European scale”, Journal of Sound and Vibration 267(3), pp. 431-437, 2003.

[13] Oertli J., “Developing noise control strategies for entire railway networks”, Journal of Sound and Vibration 293, pp. 1086-1090, 2006.

Writen by: Railteco Writen by: Railteco |  4196 like 4196 like |  2018-12-26 2018-12-26 |